Datasheet

Machine details

Technical details

- bar material dia.32 mm

- spindle passage36 mm

- turning length320 mm

- turning speeds200-8000 U/min

- Back spindle:32 mm

- turning length600 mm

- Back spindle:200 - 8000 UpM

- rapid speedx1 = 32 m/min

- rapid speedY1+Z1+X2+Z2 = 45 m/min

- controlMitsubishi M70

- Number of axles5+2x C Achse 7 St.

- Number of working hours119000 h

- spindle motor7,5/5,5 kW

- weight of the machine ca.3,5 + FMB t

- dimensions of the machine ca.2,5 x 1,2 x 1,82 plus FMB m

Zusatz

- Condition: ready for operation

- Machine still in the delivery factory

- Video(s) available on our website.

Zubehör

- bar loaderFMB Turbo 3-36 3200

- Chip conveyorCombistream 130 bar

- parts conveyor

- Parts container for long parts option

- Fire extinguish equipmentCO2

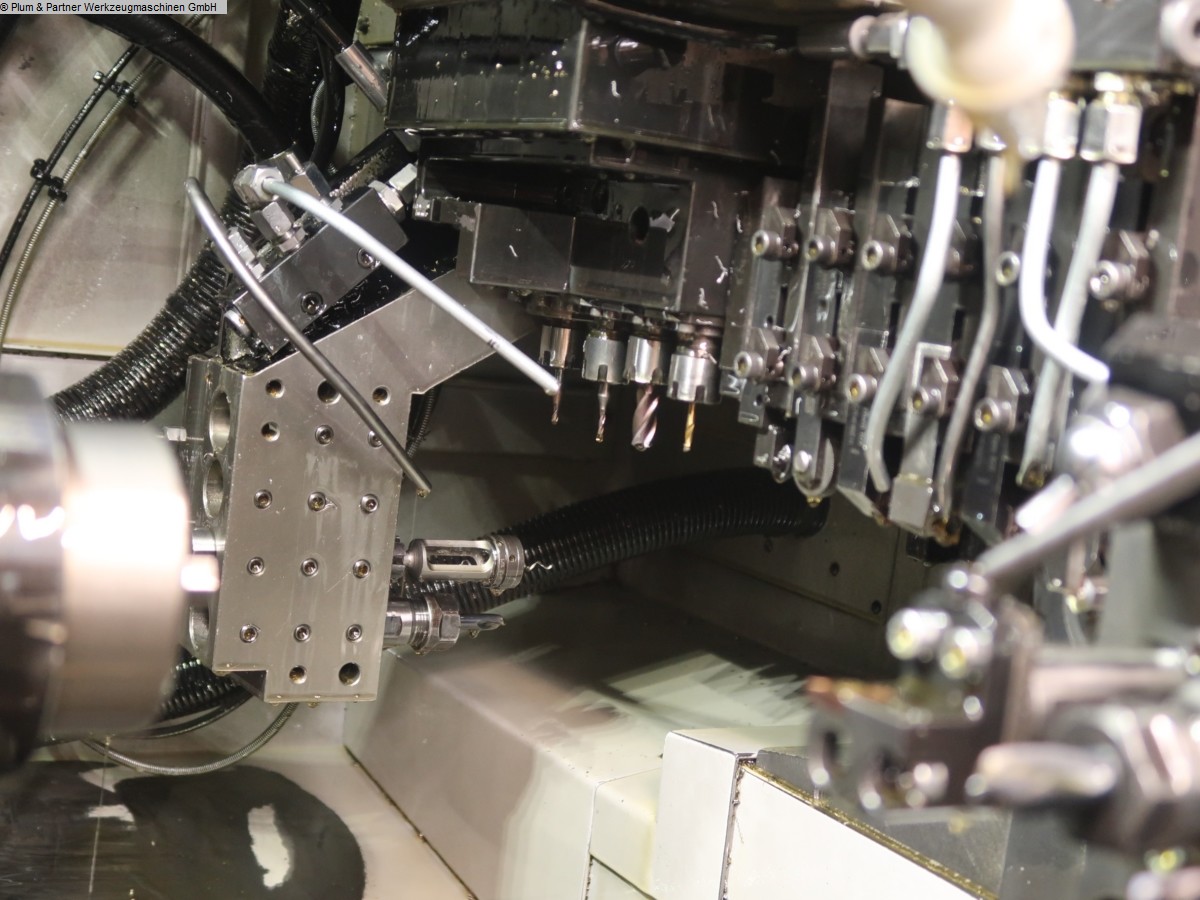

- Driven tools4 + 4

- Taperdiv.

Description

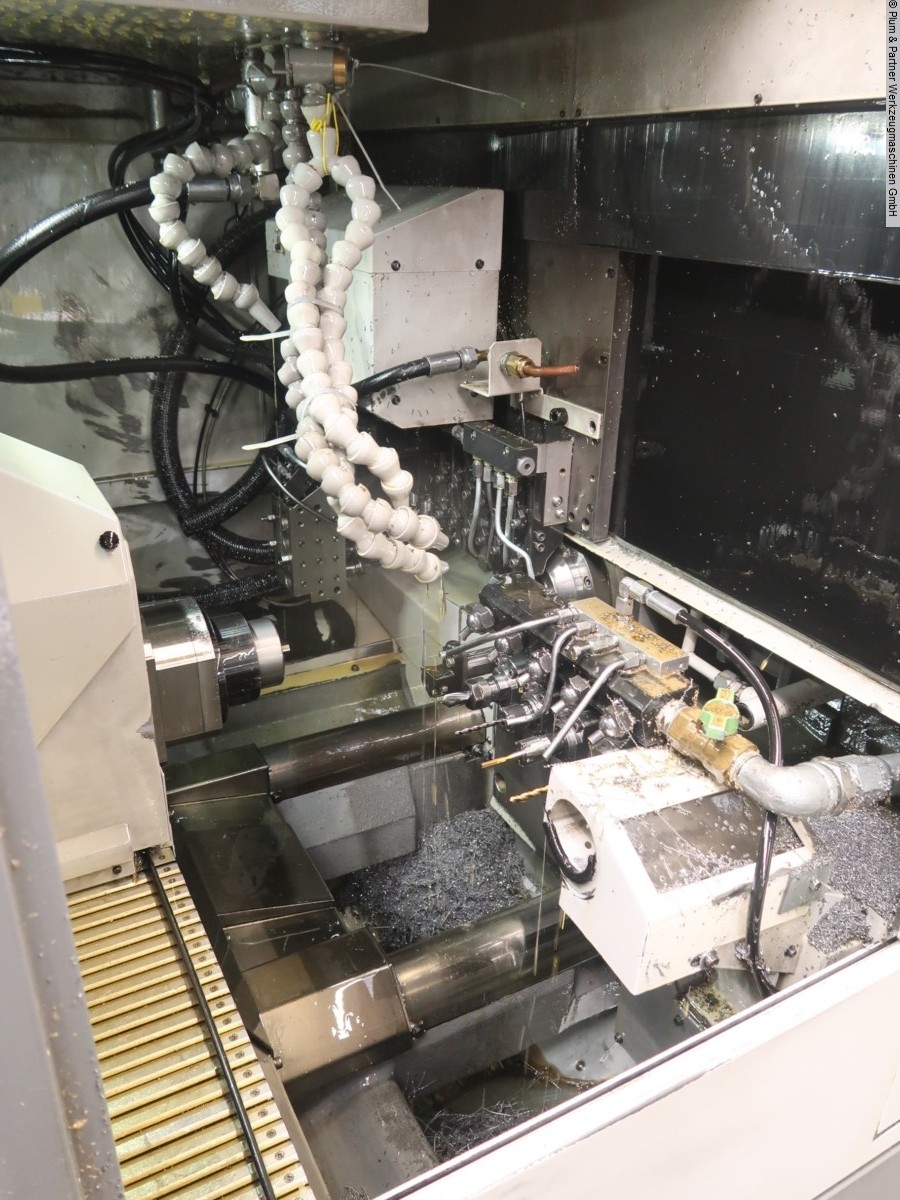

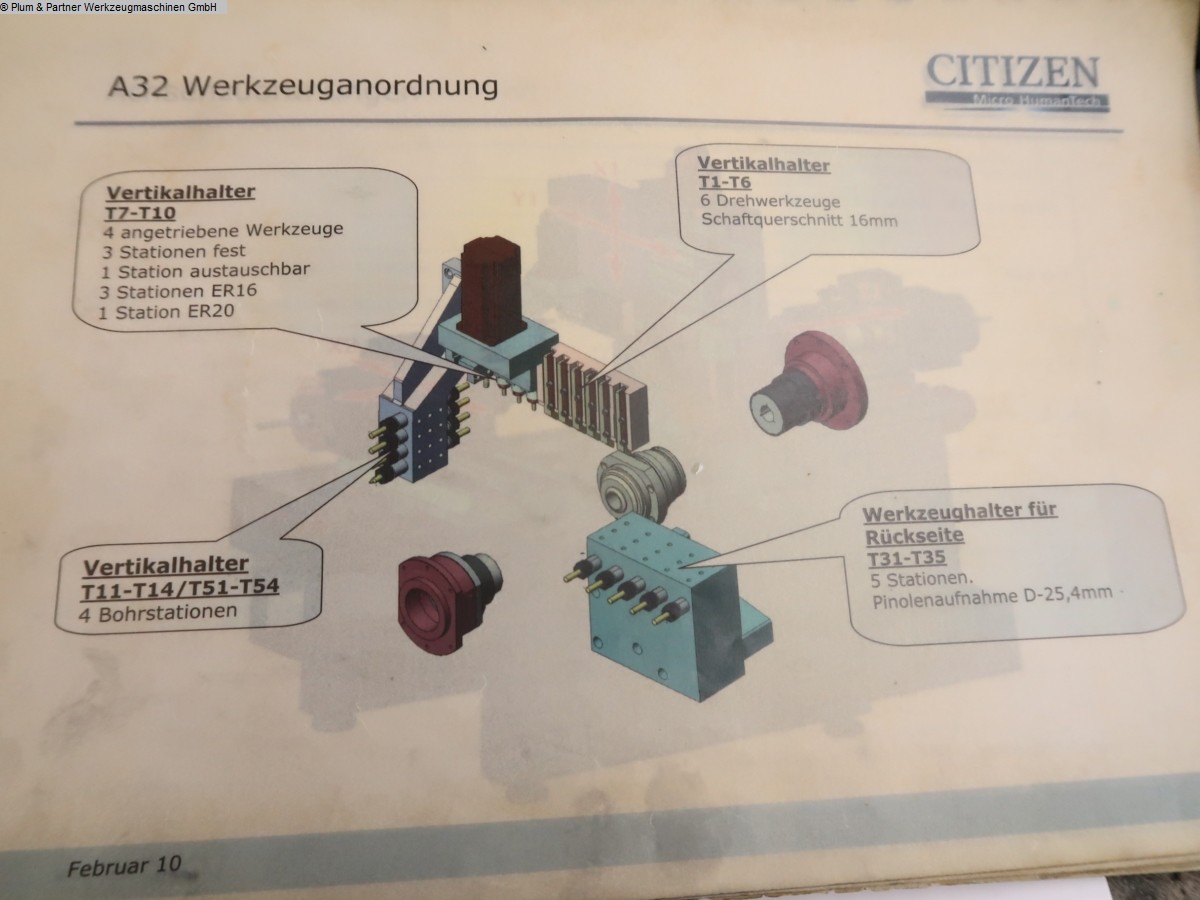

CNC Swiss-Type Lathe Citizen A32-VII (R) with FMB Turbo 3-36 3200 Var.C loading magazine. Sold due to restructuring. Machine with 7 axes (X1, Y1, Z1, X2, Z2, C1, C2) in the main spindle version on the right, vertical holder for 4 driven turning tools + 3 parting tools and + 4 drilling tools. Tool holder for the rear side with 5 stations - see sketch Figure 10. Counter (pick-off) spindle. Simultaneous machining. The machine was regularly serviced by Citizen Europe, and wear parts were last replaced in June 2025. The fire protection system was replaced in June 2025, and the bearings were replaced in June 2024. Equipment: Collet chuck for spindle + pick-off spindle / Synchronously driven guide bushing / Drive unit for guide bushing / Workpiece ejection device / Cross-machining drive unit including 4 spindles / Door lock / Pick-off spindle / Parts receiving basket + conveyor belt / Pneumatic unit for air sealing / Interior work light / 3-color warning lights / Parting tool breakage detection / COMBISTREAM high-pressure coolant system + chip conveyor, 8 outlets, 130 bar / 4-way driven tool for back machining / "Long parts" option 600 mm with parts container, guide tube, and spindle nut / Loading magazine with various material guides (7, 12, 20, 36), adapters, telescopic tubes and inserts / CO2 fire extinguishing system with FB 703 drilling system control system including flame and thermal maximum detector Manual release. Features of the CINCOM SYSTEM M70PLC CNC control system: Multi-axis CNC system for simultaneous or individual machining / Cutting radius compensation / Multiple cycle repetitions / Deep hole drilling cycle / Constant cutting speed / Chamfer and radii insertion / Constant cutting speed of the pick-up spindle / Thread chamfering on the pick-up spindle Main spindle C-axis Pick-up spindle C-axis Main and pick-up spindle synchronization / Synchronous tapping on the main and pick-up spindles as well as with the driven tools / Synchronous thread cutting on the main and pick-up spindles / Geometric function / Collision detection / 8.4" color liquid crystal display (LCD) /