Datasheet

Machine details

Technical details

- x-travel730 mm

- y-travel730 mm

- z-travel880 mm

- size of pallet2 x: 500 x 500 mm

- spindle speed:12000

- tool taperSK 40

- distance spindle center to table80 - 810 mm

- milling spindle drive30 kW

- max. torquemax. 102 Nm

- max. workpiece weight500 kg

- max. workpiece diameter on pallets800 mm

- max. workpiece heightH = 1100 mm

- change time of pallets9,5 sec

- Max. speed ot the feeder60000 mm/min

- rapid traverse60 m/min

- tool changer number of tools40

- max. tool diameter110 mm

- max. tool-dia with free toolbox320 mm

- max. tool weight30 kg

- change-time chip to chip4,4 - 10 sec

- change-time tool to tool1,95 sec

- B-axis (table)

- Number of working hours15894 h

- total power requirement46 KVA

- weight of the machine ca.15 t

- required space5,5 x 3 x 2,8 m

Zusatz

- Condition: ready for operation

Zubehör

- Electric 400 Volt

- Chip conveyor

- interior colant40 bar

- Cooling equipment

- measuring tasterRenishaw PP60op

- Machine manual

- Electr. hand wheel

Description

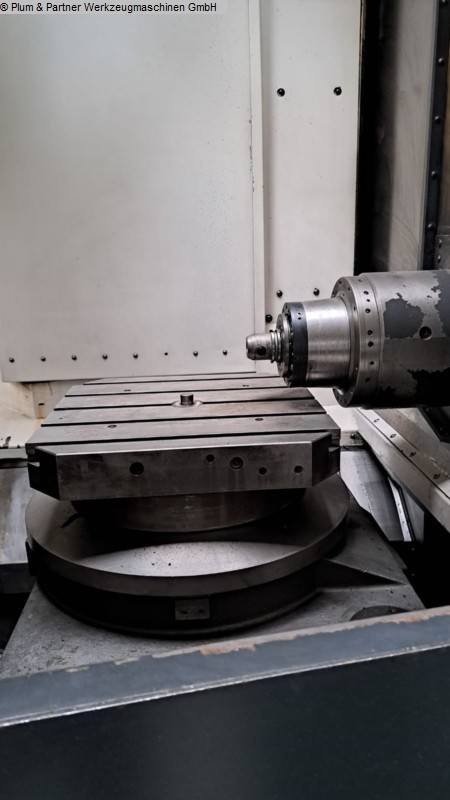

Well-preserved horizontal machining center DMG-Mori, Mod. NHX 5000, built in 2014 with Siemens 840D CNC control with two pallets and 40-way tool changer. Read operating hours 23262, spindle hours 15894 Other data: Distance spindle nose - table center 70 - 950 mm Pallet indexing time 1.3 sec Indexing of the B axis (table) 360 x 1 degree Jog feed rate 0 - 5000 mm/min Machine dealer with own stock of 1600 m².