Datasheet

Machine details

Technical details

- max. workpiece diameter40 mm

- min. workpiece diameter10 mm

- workpiece length200 - 640 mm

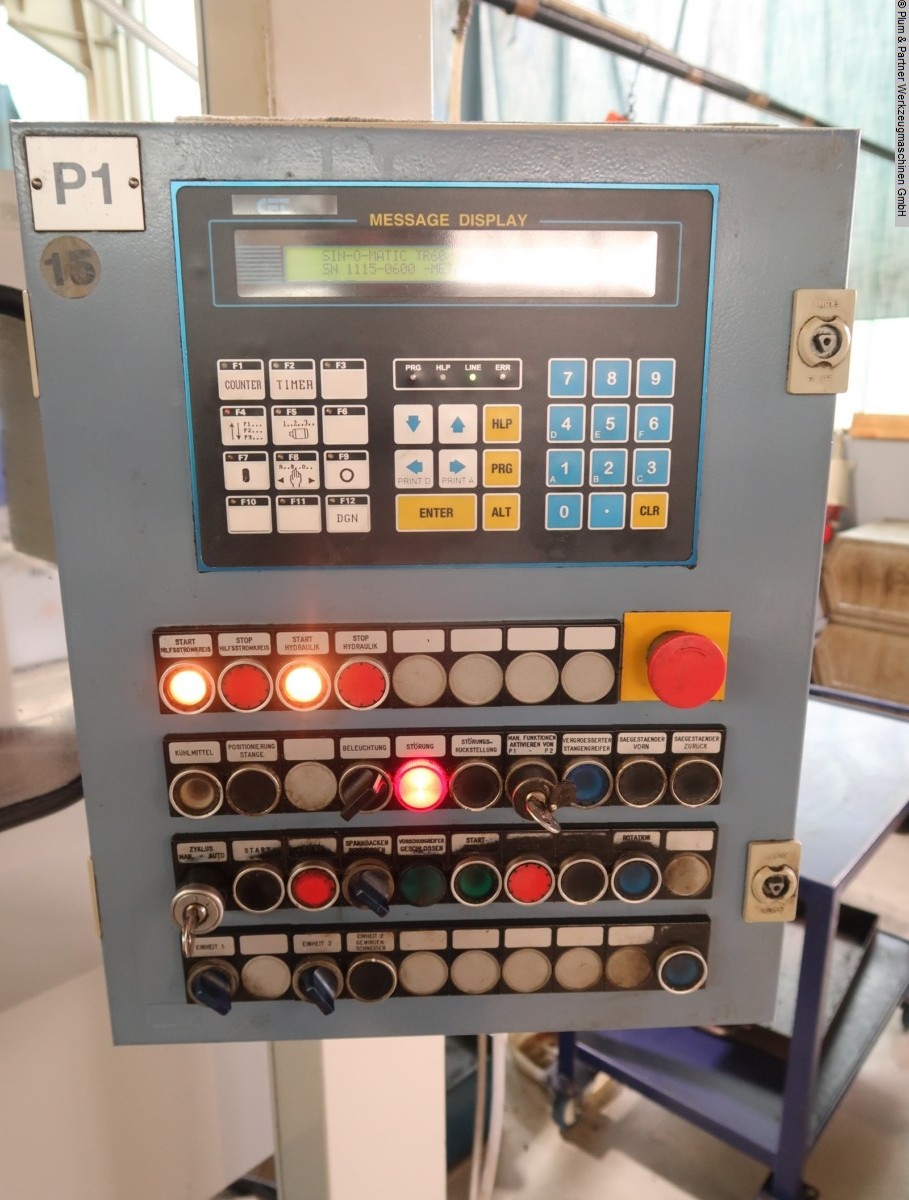

- ControlSPS Siemens S5 95 U

- total power requirement25 kW

- weight of the machine ca.5 t

- dimensions of the machine ca.8,5 x 2,8 x 2,35 m

Zusatz

- Condition: ready for operation

- CE signed

- Use: single shift

- Video(s) available on our website.

Zubehör

- Electric 380 Volt

- Bar feed and loader2 - 3,5 m

- Hydraulic-device45 bar

- Cooling equipment

- Central lubrication

- Chip conveyor

Description

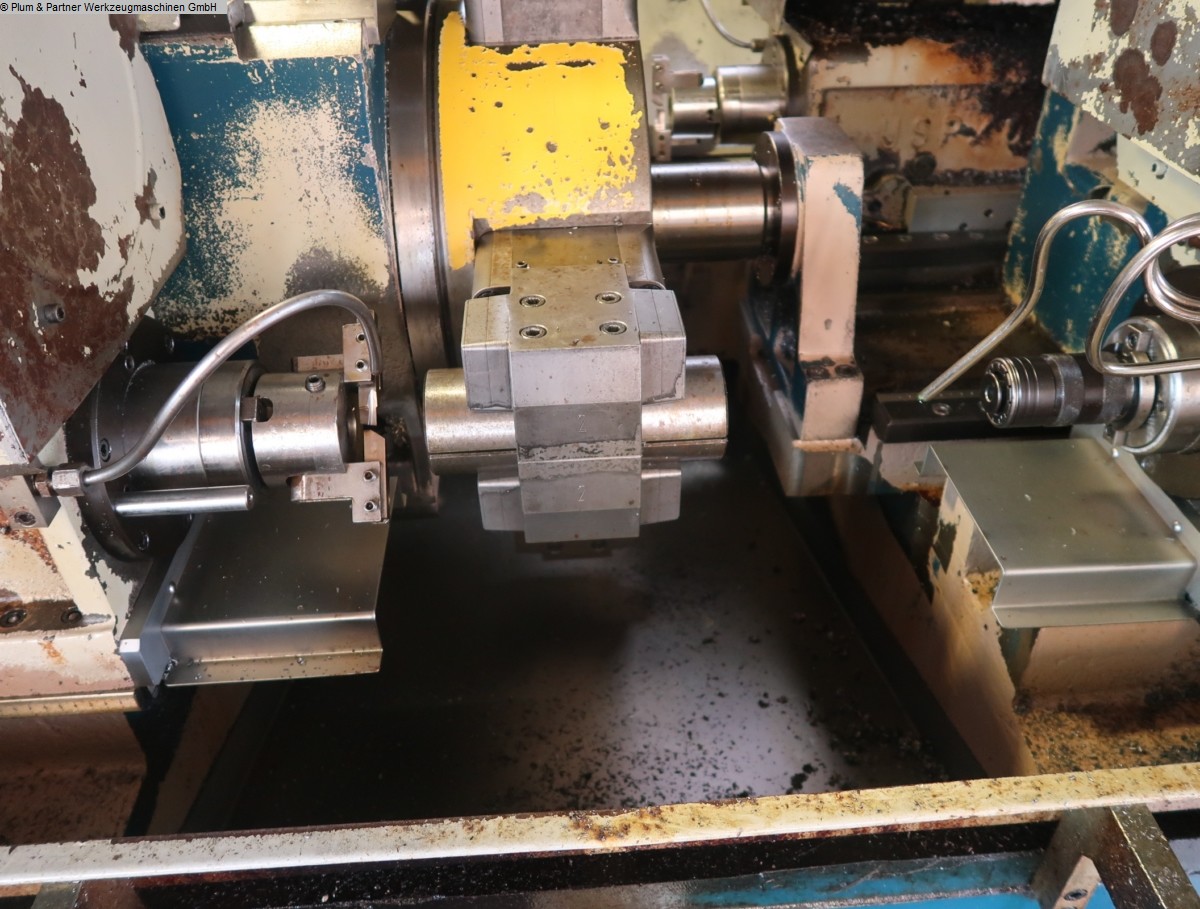

Hydraulic cutting and double-end machining machine suitable for pre-machining trapezoidal thread spindles and other round workpieces in the form of sawing off the bar and double-sided end machining such as chamfering, countersinking and drilling with fixed parts and rotating tools. Machine consisting of: - Basic machine model TR 60/4-650, passage 640 mm - Bar magazine for bar lengths 2 - 3.5 m - Normal version for solid material up to ? 40 mm - Central position of the bar feed rollers - Bar feed unit - Feed gripper in standard version - Cross switch with 4 clamping stations model TR 300.00 - 4 base jaws, width 80/140 mm, contact ? 75 mm - Swiveling cross switch in both directions - Saw unit with worm drive TR 200.00, stroke 100 mm - Saw blade 350 mm, speed 25/39 rpm - Motor power 2.6/3.2 kW - Motorized positioning of saw head - Automatic positioning of saw stand with hydraulic. Clamping - Saw blade guide - Processing unit no. 1 - USP.00/M - Speeds 842/1684 rpm, kW 3.3/4.0 - Working stroke 80 mm - Rapid feed 40 mm - Spindle mount ISA 40/M 16 - Toothed belt drive - Machining unit no. 3 - USP.00/M - Speeds 842/1684 rpm, kW 3.3/4.0 - Working stroke 80 mm - Rapid feed 40 mm - Spindle mount ISA 40/M 16 - Toothed belt drive - Machining unit no. 4 - USP.00/M - Speeds 943/1882 rpm, kW 3.3/4.0 - Working stroke 80 mm - Rapid feed 40 mm - Spindle mount ISA 40/M 16 - Unloading chute - Millimeter bars for all adjustment movements - Hydraulic system with feed pump SAUER SUNDSTRAND - Pressure accumulator - Rexroth flow regulator for machining units and saw - Coolant system with filter and container - Coolant pump CALPERA - Electrical equipment in separate electrical control cabinet, Control voltage 24V/50 Hz - PLC SIEMENS S5 95 U - Machine light - Flashing light to signal machine downtime - Central lubrication - Chip conveyor. In 2011, an extensive mechanical overhaul was carried out to optimize positioning and centering accuracy for 25.000. In addition, switches, some cables, ball bearings, seals, hydraulic hoses, etc. were replaced. The machine has hardly been used in recent years; the seller estimates the whole operating hours at around 24,000. Machine under power in sellers factory. Machine dealer with own stock of 1600 m².