Datasheet

Machine details

Technical details

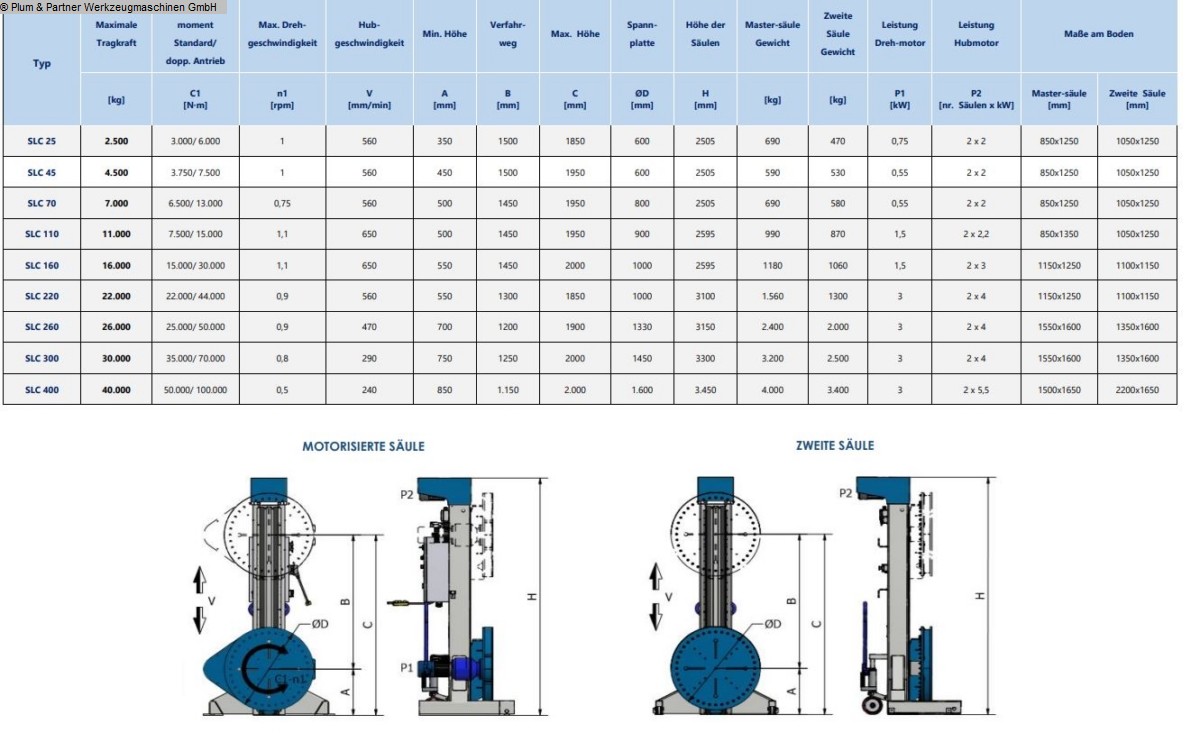

- weight max. in kg2500 kg

- Working height minimal350 mm

- Working height maximum1850 mm

- max. torque3000 Nm

- 01 U/min

- adjustment speedvertikal 560 mm/min

- vertical adjustment1500 mm

- baseplate diameter600 mm

- rotation movement0,75 kW

- stroke drive1,85 kW

- height of the plant2505 mm

- weight1160 kg

Zusatz

- Video available on our website.

Description

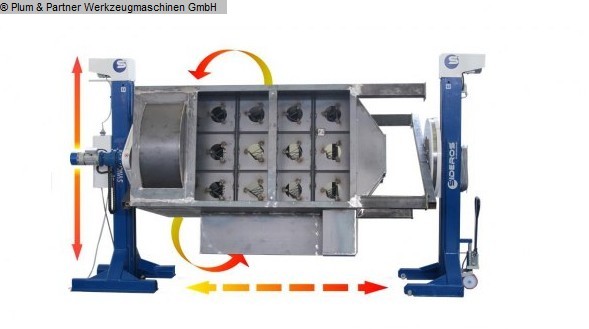

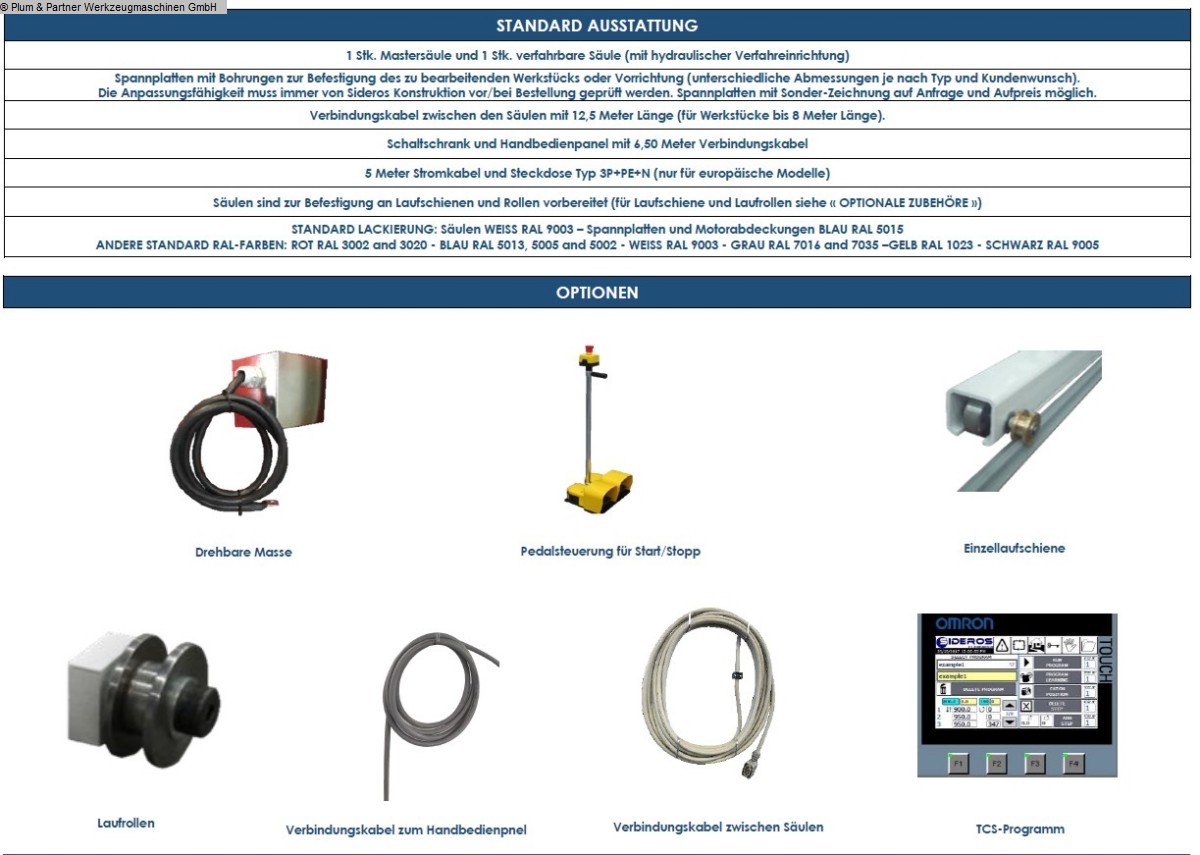

Sideros Engineering Head & Tailstock Positioners are used to weld and assembly long and large weldments in many different application fields. Besides the benefits of ergonomics and safety during welding and assembly applications, the revolutionary feature of Syncrolift is the compactness and the portability of both columns, thanks to their dedicated hydraulic jacks. The result is an extreme flexibility in the factory. Syncrolift features two main axis: Electrical elevation/descent, and Electrical 360° left/right rotation. Due to its special design, the column positioner can process very large components. Higher columns (+500/+1000/+1500 mm) for processing components with larger dimensions are available. Special equipment: Double-sided lifting drive, guide rails in 2 m segments, wireless handheld control unit, TCS program control, etc. Thanks to the movable columns, the length of the different workpieces can vary between 1 m and over 20 m. Depending on the weight and dimensions of the component, positioners with load capacities of max. 2,500 kg to max. 40,000 kg are available. Advantages: Improved Safety Proper Ergonomics Improved weld quality Cost savings and profit increase Welding/Assembly procedures repeatability Machine Features: Master and idler column with rotating mounting plates Pallet jacks for column lifting and relocating Servo-motor, ball screw and encoder control for Up & Down motion Servo-motor, gear reducer and encoder control for Rotation LCD display for positioning set up, safety thresholds setting and diagnostic Automatic load leveling Redundant safeties - servo motor brake, ball screw thread geometry and mechanical Stopper Low maintenance 240/480/600 Volt - 3 phase - 60 Hz In order to configure the system precisely to meet the requirements, we must obtain all relevant information about the workpieces to be processed for the manufacturer's technical office. There we have a list of questions for this purpose.